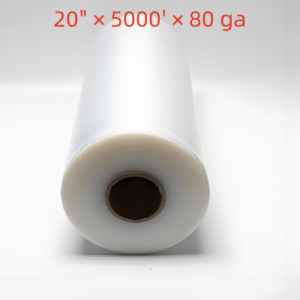

Stretch film is a type of plastic film that is used primarily for securing and protecting products during storage and transportation.

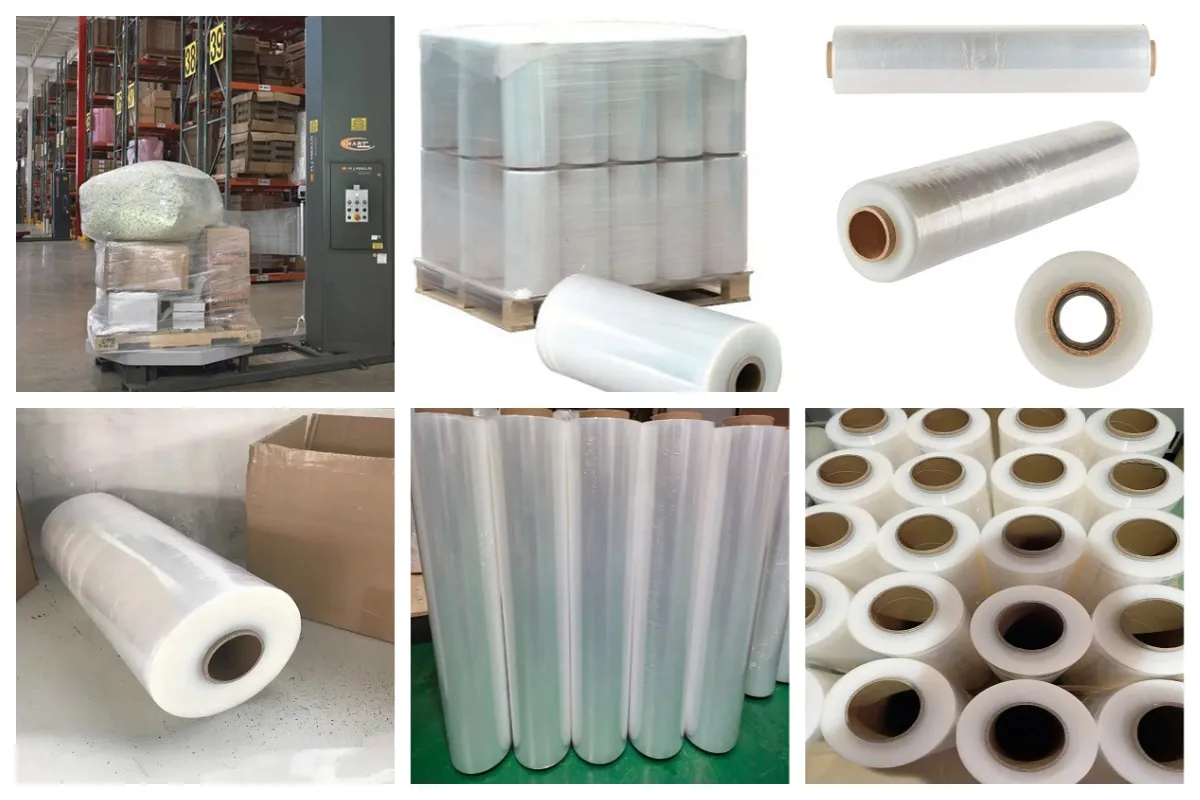

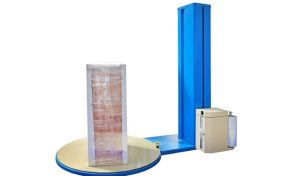

Functionality: Stretch film is designed to stretch and cling to objects, providing a tight, secure wrap. When the film is stretched and applied to a product or pallet, it creates a strong, protective layer that helps to keep items together and prevent movement during transit. This clinging effect reduces the likelihood of damage caused by shifting or impacts.

Applications: Stretch film is widely used in various industries, including warehousing, logistics, and manufacturing. It is often employed to wrap pallets of goods, protecting them from dust, dirt, and moisture. The film’s elasticity allows it to conform to the shape of the items being wrapped, offering a snug fit that minimizes the risk of shifting or damage.

Benefits:

Enhanced Protection: Stretch film provides a barrier against environmental factors, such as dust and moisture, helping to keep products clean and dry.

Tamper Evidence: When used correctly, stretch film can act as a tamper-evident seal, ensuring that the contents remain secure and intact.

Cost-Effectiveness: Stretch film is generally affordable and can be applied quickly and easily, making it a popular choice for high-volume packaging.Stretch film is a type of plastic film that is used primarily for securing and protecting products during storage and transportation.

Functionality: Stretch film is designed to stretch and cling to objects, providing a tight, secure wrap. When the film is stretched and applied to a product or pallet, it creates a strong, protective layer that helps to keep items together and prevent movement during transit. This clinging effect reduces the likelihood of damage caused by shifting or impacts.

Applications: Stretch film is widely used in various industries, including warehousing, logistics, and manufacturing. It is often employed to wrap pallets of goods, protecting them from dust, dirt, and moisture. The film’s elasticity allows it to conform to the shape of the items being wrapped, offering a snug fit that minimizes the risk of shifting or damage.

Benefits:

Enhanced Protection: Stretch film provides a barrier against environmental factors, such as dust and moisture, helping to keep products clean and dry.

Tamper Evidence: When used correctly, stretch film can act as a tamper-evident seal, ensuring that the contents remain secure and intact.

Cost-Effectiveness: Stretch film is generally affordable and can be applied quickly and easily, making it a popular choice for high-volume packaging.