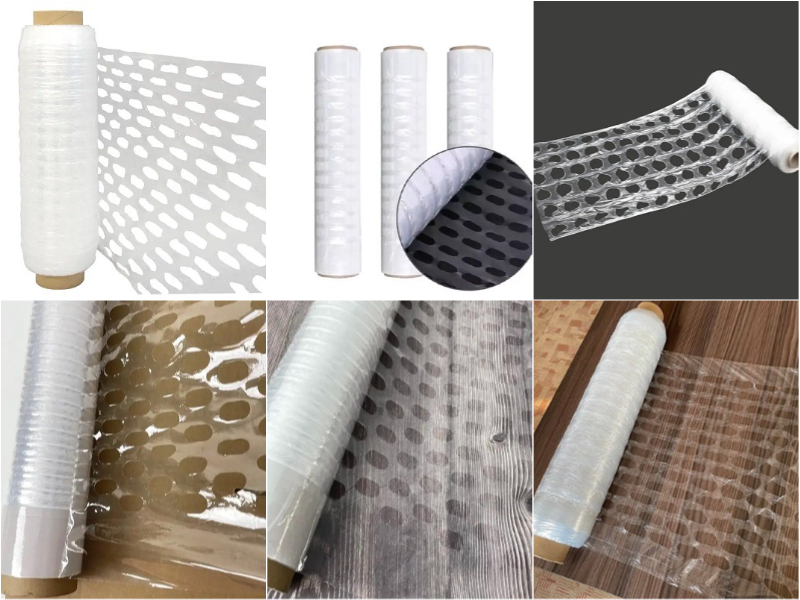

Manual breathable stretch film is an innovative solution designed to meet the specific needs of industries requiring airflow during packaging. Unlike traditional stretch films, manual breathable stretch film is pre-perforated, allowing air to circulate and reducing condensation—a critical factor for sectors like food, pharmaceuticals, and agriculture. This hand stretch film type offers a perfect balance between secure packaging and maintaining product integrity, as it prevents moisture buildup, spoilage, and bacteria growth. For industries transporting fresh produce, frozen foods, and temperature-sensitive products, breathable stretch film ensures safe transit and optimal shelf life. Its manual application also makes it ideal for small-scale businesses that prioritize cost-effective and reliable packaging solutions. Manual breathable stretch film is a perforated, pre-stretched film that ensures airflow and minimizes condensation, ideal for refrigerated and food products.

Why Choose Our Stretch Film Over Competitors?

| Attributes | Details |

|---|---|

| Place of Origin | Fujian, China |

| Brand Name | PWP Stretch Film |

| Product Name | Manual Breathable Stretch Film |

| Material | High Density Polyethylene |

| Features | Breathable Packaging, Perforation, Anti-Condensation |

| Hardness | Soft |

| Processing Type | Multiple Extrusion, Casting, Blow Molding |

| Transparency | Transparent |

| Color | Transparent |

| Thickness | Customized |

| Length | Customized |

| Width | Customized |

| Size | Customized |

| Tensile Strength | 0.0-50.0MPa |

| Surface | Smooth, Plain, High Gloss, Glossy |

| OEM | Avaliable |

| Certificate | ISO, ROHS |

| Use | Fruits, Flowers, Food, Pharmaceutical Products |

| Sales Unit | Single Item |

Manual breathable stretch film is a specialized packaging material that provides both secure wrapping and ventilation. Unlike traditional stretch films, manual breathable stretch film includes pre-made perforations or vented patterns, allowing consistent airflow. This ventilation minimizes condensation and reduces the likelihood of moisture accumulation within the packaging. For sensitive products like produce, dairy, frozen items, and pharmaceuticals, this air circulation is essential to maintain freshness, prevent mold or bacteria growth, and ensure that products arrive in optimal condition.

| Feature | Manual Breathable Stretch Film | Standard Stretch Film |

|---|---|---|

| Ventilation | Designed with perforations for airflow | No perforations; minimal or no airflow |

| Application | Manual application; ideal for small businesses | Available in both manual and machine-applied forms |

| Moisture Control | Reduces condensation, ideal for perishable goods | Can trap moisture, unsuitable for certain temperature-sensitive items |

| Product Freshness | Maintains product integrity and freshness | Less suitable for fresh produce, plants, or frozen goods |

| Stretchability | Stretches up to 50% without losing ventilation properties | Varies; typically stretches more but lacks ventilation |

Manual breathable stretch film’s unique ventilation allows it to support a wider range of products in various conditions, especially when condensation control is crucial.

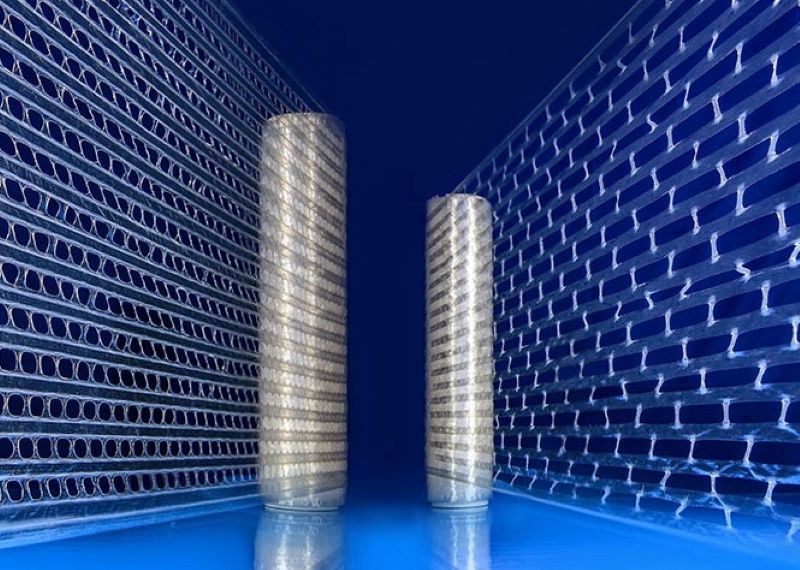

Manual Pre-Stretched Vented Stretch Film is a specialized packaging material designed for hand application, offering superior load stability, reduced film usage, and enhanced airflow for perishable or moisture-sensitive goods. It combines the benefits of pre-stretching technology with perforations to optimize performance in manual wrapping scenarios.

Key Features

Material & Specifications

Advantages Over Traditional Stretch Film

This film is ideal for industries prioritizing efficiency, product freshness, and sustainable packaging solutions.

Manual breathable stretch film is a specialized packaging material designed to secure and protect products while allowing controlled air circulation. It combines the elasticity of traditional stretch film with micro-perforations or a porous structure to enable airflow, making it ideal for applications where moisture control or ventilation is critical. Below is a detailed explanation of its working mechanism, materials, and applications:

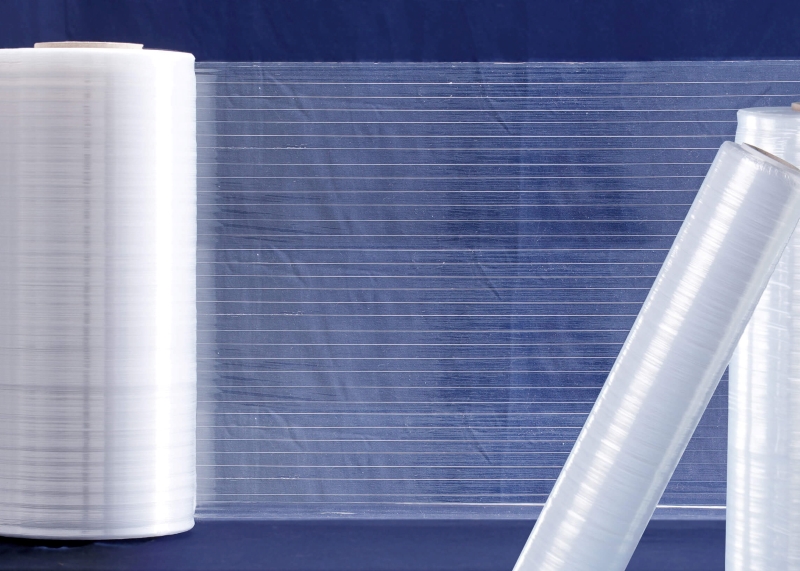

Like conventional stretch film, the manual breathable variant relies on:

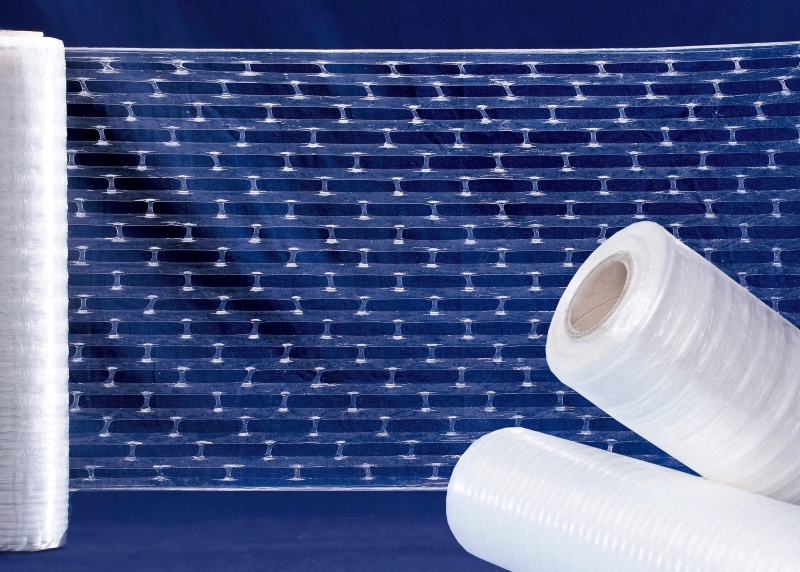

The key difference lies in its ability to “breathe”:

Breathable stretch film is applied manually using handheld dispensers or by hand:

Manual breathable stretch film works by combining stretchability with controlled ventilation through micro-perforations or porous materials. Its design addresses the need for both product security and environmental management, making it indispensable in industries where airflow and moisture control are paramount.

Manual breathable stretch film is engineered to balance strength, elasticity, and airflow, making it suitable for applications requiring both load stability and environmental control. Below are the critical specifications that define its performance and usability:

FDA Compliance: Required for films contacting food products (e.g., fresh produce packaging).

ASTM D882: Standard test method for tensile properties of thin plastic sheeting.

ISO 4591: Measurement of perforation size and distribution.

| Parameter | Typical Range |

|---|---|

| Thickness | 12–30 microns |

| Perforation Size | 50–200 microns |

| MVTR | 500–2,000 g/m²/day |

| Stretchability | 200–300% elongation |

| Roll Width | 30–50 cm |

| Cling Force | 50–300 g/cm² |

| UV Resistance | 6–12 months outdoors |

| Tensile Strength | 20–40 MPa |

| Temperature Tolerance | -40°C to 60°C |

Using manual breathable stretch film offers numerous benefits that make it an excellent choice for businesses requiring breathable packaging solutions. Designed to balance ventilation and durability, this type of stretch film provides unique advantages for a range of products, especially in industries where freshness, moisture control, and sustainability are paramount. The stretch film production process plays a critical role in achieving these qualities, as it involves carefully selecting materials and techniques to ensure the film’s breathability and strength. This ensures optimal protection while maintaining product integrity during transport and storage.

One of the main advantages of manual breathable stretch film is its cost-efficiency. Small businesses or operations with limited packaging budgets benefit greatly from this film’s affordability and ease of use, eliminating the need for expensive machinery. Many suppliers source these films from specialized stretch film factory, which focus on producing high-quality, cost-effective options tailored for manual applications. Manual breathable stretch film is straightforward to apply by hand, saving on equipment costs and reducing overhead expenses, making it an ideal solution for businesses needing an efficient, cost-effective packaging option.

Manual breathable stretch film is highly effective at minimizing moisture buildup, a crucial factor for preserving product quality. The ventilation properties of this film allow for controlled airflow, which prevents condensation within the wrapped product. This is particularly beneficial for perishable items, as it reduces the risk of mold and spoilage. Products like fresh produce, flowers, and dairy items remain fresh longer, as the breathable film supports an ideal storage environment that combats excess humidity.

Durability is essential in stretch film, especially for manually applied films. Manual breathable stretch film combines flexibility with strength, allowing it to stretch efficiently without tearing, even when applied to irregularly shaped loads. This flexibility ensures a secure wrap while maintaining the breathable properties that protect product integrity. The chemistry stretch film is formulated to enhance these qualities, offering superior stretch and conformability. The film’s ability to stretch and conform to different load types provides reliable support, keeping products stable during transport.

Made from recyclable materials such as mLLDPE, manual breathable stretch film aligns with environmental sustainability goals. This film is fully recyclable, reducing plastic waste and providing a more sustainable alternative to traditional packaging options. Businesses that prioritize eco-friendly practices find that using manual breathable stretch film helps to reduce their environmental footprint while meeting packaging needs, making it a favorable choice for companies and industries aiming for greener operations.

The breathable design of manual breathable stretch film also helps in maintaining temperature control. By allowing air circulation, this film minimizes temperature fluctuations, making it ideal for products that need a stable climate. Pharmaceuticals, frozen foods, and other temperature-sensitive items benefit from this feature, as it helps maintain product quality even during long transit times.

Manual breathable stretch film is suitable for a diverse range of industries, from food and pharmaceuticals to horticulture and consumer goods. Its unique combination of ventilation, durability, and flexibility makes it adaptable to many different packaging scenarios, allowing businesses in various sectors to benefit from its specialized design. This versatility ensures that products are safely and securely wrapped, extending shelf life and preserving quality across multiple applications.

The advantages of manual breathable stretch film extend from cost savings and moisture reduction to improved durability and sustainability, offering a comprehensive packaging solution for companies seeking reliable, breathable packaging options.

By understanding these types and sizes, businesses can select the most appropriate manual breathable stretch film for their specific packaging needs.

Manual breathable stretch film offers a range of advantages that make it ideal for packaging sensitive and perishable goods. Here’s a breakdown of its key characteristics:

Air Permeability

Versatility in Application

Cost-Effective

Speed and Ease of Use

Increased Strength and Stability

Environmental Sustainability

Optimal for Various Products

Elasticity and Flexibility

Improved Factory Efficiency

With these features, manual breathable stretch film provides a versatile, cost-effective, and eco-friendly solution for packaging sensitive items, enhancing efficiency and protecting products during storage and transit.

Manual breathable stretch film is designed for industries that need ventilation in their packaging to preserve product quality and freshness. This film type is highly versatile and widely used to address specific packaging needs in industries such as food, pharmaceuticals, floral, and pet food, where maintaining the right balance of airflow and protection is essential. By providing necessary ventilation, breathable hand stretch film helps prevent condensation, stabilize temperatures, and extend shelf life.

Manual breathable stretch film offers a versatile solution for various industries, particularly in sectors where airflow, moisture control, and product integrity are critical. Below is a detailed breakdown of how manual breathable stretch film is used in several key applications:

Manual breathable stretch film is widely used in the food industry, particularly for perishable items, as it helps maintain freshness and extend shelf life.

In the pharmaceutical sector, manual breathable stretch film is used to protect sensitive items that require strict temperature and humidity control.

Manual breathable stretch film is not limited to food and pharmaceuticals. It also serves various other sectors, offering protection and stability for a wide range of products:

In conclusion, manual breathable stretch film is a versatile, cost-effective, and environmentally friendly solution used across multiple industries. Its ability to allow airflow while preventing condensation makes it ideal for packaging and protecting a wide variety of products, ensuring that they remain fresh, safe, and in optimal condition throughout storage and transport.

The production of manual breathable stretch film involves specialized techniques to combine elasticity, cling, and controlled airflow. The process integrates polymer science, precision engineering, and quality control to meet performance specifications. Below is a detailed breakdown of the manufacturing steps, technologies, and critical considerations:

Breathable stretch film is typically produced via blown film extrusion or cast extrusion, with blown extrusion being more common for multi-layer films.

The breathability is achieved through mechanical perforation or in-situ pore formation:

Manufacturing manual breathable stretch film requires precision in material selection, extrusion, and perforation technologies to achieve the optimal balance of stretch, cling, and breathability. Advances in laser perforation, multi-layer co-extrusion, and biodegradable materials continue to expand its applications. Producers must tailor processes to meet industry-specific requirements, ensuring compliance with performance standards while minimizing environmental impact.

Choose PWP Stretch Film for reliable, high-quality, and cost-effective manual breathable stretch film solutions tailored to your business needs.

Stretch wrap and stretch film essentially refer to the same product, and the terms are often used interchangeably. Both are types of plastic films that are highly elastic and used for wrapping around items to keep them secure during transportation or storage. Stretch wrap is typically available in rolls and can be manually or machine-applied to products. The primary difference lies in the usage of the terms in different regions or industries. “Stretch wrap” often refers more to the action or process of wrapping, whereas “stretch film” refers to the material itself. Regardless of the term used, both serve the same function – to provide stability to pallet loads, protect products, and reduce damage during transit.

Cling film and stretch film serve different purposes and are therefore manufactured differently. Cling film, also known as plastic wrap or food wrap, is a thin plastic film used primarily to cover food items to keep them fresh. It is designed to cling tightly to the surface of containers or foods, preventing air from entering. Cling film is generally made from polyvinyl chloride (PVC) or low-density polyethylene (LDPE). On the other hand, stretch film is a highly elastic plastic film typically made from linear low-density polyethylene (LLDPE). It is used in industrial settings to secure pallet loads. Stretch film has superior tensile strength compared to cling film and is designed for load stability rather than food preservation. While both films are stretchy, the key difference lies in their applications: cling film is for domestic use in food wrap, and stretch film is for industrial use in packaging and load securing.

Blown film and stretch film are terms that describe different types of plastic films with distinct manufacturing processes and applications. Blown film is produced using the blown film extrusion process, where molten polymer is extruded through a circular die and inflated to form a thin film. This process gives blown film excellent strength, toughness, and resistance to punctures and tearing. It is commonly used for products like grocery bags, agricultural films, and packaging materials. Stretch film, specifically designed for wrapping and securing pallet loads, is typically made through the cast extrusion process. This method involves extruding molten plastic through a flat die and cooling it quickly, resulting in a highly elastic film with smooth surfaces and consistent thickness. While both blown film and stretch film are used in packaging, the former is valued for its durability and barrier properties, while the latter is prized for its high stretchability and ability to secure loads efficiently.

Stretch hood and stretch film are both used for securing and protecting palletized loads but differ significantly in their design and application. Stretch hood is a type of packaging material that comes in a tubular form with one end sealed. It creates a “hood” that stretches over the top and sides of a pallet load. Stretch hood films are highly elastic, offering excellent stability and protection against environmental factors. The application process typically involves a machine that stretches the hood over the pallet, making it ideal for high-volume operations. In contrast, stretch film is applied by wrapping layers of film around the load. It can be applied manually or by machine and is often available in rolls. Stretch film is versatile and effective for securing loads but generally requires more time and labor compared to the automated application of stretch hoods. The primary differences between the two lie in their shapes (tubular versus flat) and application methods (hooding versus wrapping), with stretch hoods offering greater efficiency and stability for large-scale operations.

Stretch film comes in several different types, each designed to meet specific packaging needs. Among these, manual breathable stretch film is a specialized option primarily used for wrapping goods that require airflow during storage and transport. While there are many types of stretch film, they can generally be classified into a few main categories:

Cast Stretch Film – Known for its clarity and ease of use, cast stretch film is commonly used in manual applications. It provides strong cling and elasticity but does not offer breathability.

Blown Stretch Film – Offers superior strength and puncture resistance but lacks breathability. It is used for heavier loads but may not be suitable for products that need ventilation.

Manual Breathable Stretch Film – Specifically designed for wrapping items that require ventilation, such as fresh produce, flowers, and other perishable goods. The breathable properties allow air to circulate, reducing the risk of spoilage.

Thus, manual breathable stretch film is a specialized variant that addresses the need for ventilation in packaging, while other stretch films focus on strength, clarity, or puncture resistance.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed