Did you know that over 5 million tons of plastic pallet wrap end up in landfills and oceans annually in the U.S. alone? As governments tighten regulations—like California’s SB 54 mandating a 65% reduction in single-use plastics by 2032—businesses face mounting pressure to adopt sustainable alternatives. Enter biodegradable pallet wrap: a game-changer blending environmental responsibility with commercial practicality.

Unlike traditional plastic films, which linger for centuries, biodegradable options decompose within months under proper conditions, slashing carbon footprints while safeguarding compliance. But beyond ‘eco-friendly pallet wrap,’ this innovation delivers tangible ROI. A 2023 study by McKinsey revealed that companies switching to eco-friendly packaging saw a 12–15% boost in customer loyalty and reduced regulatory risks.

In this article, we’ll explore why biodegradable plastic pallet wrap isn’t just a trend but a strategic necessity—covering its science-backed benefits, cost-saving potential, and how to partner with certified suppliers to future-proof your operations.

Biodegradable pallet wraps are engineered to balance durability during use and rapid decomposition post-disposal. Their unique material composition and scientifically validated degradation mechanisms make them a sustainable alternative to traditional plastic wraps. Below is a detailed breakdown:

Pallet wrap biodegradables are typically formulated from a blend of organic and bio-based polymers. Common materials include:

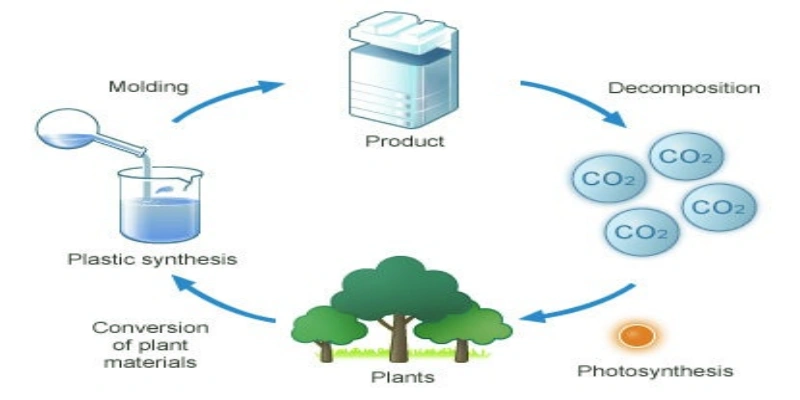

Biodegradable wraps decompose through enzymatic action by microorganisms, breaking down into water, CO₂, and biomass. The process varies by environment:

| Property | Biodegradable Wrap | Traditional LLDPE Plastic |

|---|---|---|

| Tensile Strength | 80–90% of LLDPE* | 100% |

| Degradation Time | 3 months–5 years | 500+ years |

| Carbon Footprint | 50–70% lower | High |

| Cost | 20–30% higher initially | Low |

To ensure authenticity, prioritize suppliers with:

A U.S. logistics company replaced LLDPE wraps with a PBAT/PLA blend, achieving:

Biodegradable pallet wraps leverage advanced polymer science to deliver functionality without environmental harm. By understanding their material makeup and degradation pathways, businesses can select products aligned with both operational needs and ESG goals. Always verify certifications and conduct pilot tests to ensure compatibility with your supply chain.

Environmental certifications are critical to verifying claims about biodegradable pallet wraps. Without third-party validation, “biodegradable” labels risk being greenwashing. This section explains the most recognized certifications, their requirements, and how to ensure compliance.

Certifications are non-negotiable for authentic biodegradable pallet wraps. They bridge the gap between marketing claims and scientific proof, ensuring products deliver on their environmental promises. Always prioritize suppliers with transparent, third-party certifications and align choices with your disposal infrastructure.

Biodegradable pallet wraps offer significant environmental benefits, but their performance and eco-effectiveness depend heavily on proper handling, storage, and disposal. Ignoring these precautions can lead to premature degradation, compromised functionality, or failure to meet sustainability goals. Below are critical precautions to ensure optimal results:

Biodegradable wraps are sensitive to environmental factors. Improper storage can degrade the material before use:

Failure to dispose of biodegradable wraps correctly negates their eco-benefits:

Biodegradable pallet wraps demand a disciplined approach to storage, handling, and disposal. By adhering to these precautions, businesses can maximize performance, avoid greenwashing accusations, and achieve genuine environmental impact. Always align your operational practices with the product’s scientific limitations and certifications—sustainability is a process, not a label.

Choosing between biodegradable pallet wrap and traditional plastic stretch film involves trade-offs between sustainability, performance, and cost. Below is a detailed comparison across critical factors, including tensile strength, waterproofness, puncture resistance, cost-effectiveness, and applicability to specialized scenarios like cold chain logistics or heavy pallets.

| Aspect | Biodegradable Pallet Wrap | Traditional Plastic (LLDPE) |

|---|---|---|

| Strength | 80–90% of LLDPE* (e.g., PBAT/PLA blends) | 100% (Industry benchmark) |

| Pre-Stretch Capacity | Limited to 50–70% stretch to avoid tearing. | Can stretch 100–150% without breaking. |

| Adaptability | Requires careful tension control during wrapping. | Consistent performance across machines. |

Key Insight: Biodegradable wraps are suitable for light-to-medium loads but may need additional layers for heavy-duty use.

| Aspect | Biodegradable Pallet Wrap | Traditional Plastic (LLDPE) |

|---|---|---|

| Material Toughness | Lower (e.g., PLA is brittle; PBAT is more elastic). | High resistance to sharp edges. |

| Mitigation | Use edge protectors or apply 3–5 layers. | Standard 2–3 layers suffice. |

| Heavy Pallets | Risk of tearing with loads >1,500 lbs. | Reliable for ultra-heavy loads (2,000+ lbs). |

Key Insight: Traditional plastic is superior for long-term moisture protection, while biodegradable options require material-specific selection (e.g., PBAT for damp conditions).

| Aspect | Biodegradable Pallet Wrap | Traditional Plastic (LLDPE) |

|---|---|---|

| Material Toughness | Lower (e.g., PLA is brittle; PBAT is more elastic). | High resistance to sharp edges. |

| Mitigation | Use edge protectors or apply 3–5 layers. | Standard 2–3 layers suffice. |

| Heavy Pallets | Risk of tearing with loads >1,500 lbs. | Reliable for ultra-heavy loads (2,000+ lbs). |

Key Insight: Biodegradable wraps may require reinforced application techniques for heavy or sharp-edged cargo.

| Aspect | Biodegradable Pallet Wrap | Traditional Plastic (LLDPE) |

|---|---|---|

| Upfront Cost | 20–30% higher per roll. | Low cost due to mature production. |

| Long-Term Savings | - Avoid plastic taxes (e.g., EU €800/ton levy). - Enhanced brand value and customer loyalty. - Reduced waste management fees (if composted). | Higher regulatory risks and potential fines. |

| ROI Example | A UK retailer saved 12% annually by switching to biodegradable wraps and leveraging tax incentives. | Short-term savings but rising compliance costs. |

Key Insight: Biodegradable wraps offer long-term financial benefits for sustainability-focused businesses.

Biodegradable pallet wraps are viable for light-to-medium applications and align with sustainability mandates but require compromises in extreme conditions. Traditional plastic remains unbeaten for heavy-duty, cold chain, or cost-sensitive operations. The optimal choice depends on balancing operational needs, environmental commitments, and total cost of ownership.

Choosing between manual (hand) and machine-applied biodegradable stretch wrap depends on operational scale, labor costs, and performance requirements. Below is a detailed breakdown of their pros, cons, and ideal use cases:

| Factor | Hand-Applied Biodegradable Wrap | Machine-Applied Biodegradable Wrap |

|---|---|---|

| Application Speed | 10–15 pallets/hour (manual labor). | 30–60 pallets/hour (automated systems). |

| Pre-Stretch Capacity | Limited to 50–70% stretch (risk of tearing). | Up to 250% stretch (machine-controlled). |

| Consistency | Variable tension based on operator skill. | Uniform tension for load stability. |

| Labor Cost | High (requires skilled workers). | Low (minimal staffing post-setup). |

| Upfront Investment | Low (0.10–0.50 per wrap dispenser). | High (5000–50,000 for machinery). |

| Cost Factor | Hand Wrap | Machine Wrap |

|---|---|---|

| Film Cost | 150/month(20rollsat7.50/roll). | 120/month(15rollsat8/roll). |

| Labor Cost | 800/month(10hoursat80/hour). | $0 (automated). |

| Equipment Cost | $50 (dispenser). | $8,000 (semi-auto machine). |

| Total Annual Cost | $11,750 | $9,440 (ROI in ~8 months). |

| Cost Factor | Hand Wrap | Machine Wrap |

|---|---|---|

| Film Cost | $1,500/month. | $1,000/month. |

| Labor Cost | $8,000/month. | $500/month (maintenance). |

| Equipment Cost | $500 (multiple dispensers). | $35,000 (fully automated system). |

| Total Annual Cost | $114,500 | $49,000 (ROI in ~5 months). |

Key Insight: Machines save costs at scale but require biodegradable films compatible with high pre-stretch.

Hand-applied biodegradable wrap suits small businesses with varied, low-volume needs, while machine application delivers efficiency and savings for large-scale operations. The choice hinges on balancing volume, load types, and sustainability targets. Always verify biodegradable film compatibility with your chosen method to avoid performance issues.

The wholesale price of biodegradable stretch film varies significantly based on material composition, certifications, order volume, and regional market dynamics. Below is a detailed breakdown of pricing factors, current trends, and strategies to secure cost-effective deals.

| Factor | Price Impact |

|---|---|

| Material Composition | - PLA-based: 0.08–0.12 per sqm (cheapest). - PBAT/PLA blends: 0.15–0.25 per sqm. - PHA-based: 0.30–0.50 per sqm (highest due to production costs). |

| Certifications | BPI, TUV, or EN 13432 certifications add 15–25% to the base price. |

| Order Volume | Bulk orders (10,000+ rolls) reduce costs by 20–40% (economies of scale). |

| Film Thickness | Thicker films (20–30 microns) cost 10–15% more than standard (15–20 microns). |

| Region | - US/Europe: Higher prices due to compliance costs. - Asia: Cheaper but quality varies (e.g., China: 0.07–0.18 per sqm). |

Wholesale biodegradable stretch film prices range from 0.08/sqm(basicPLA) to 0.50/sqm (premium PHA), with bulk orders and strategic sourcing offering significant savings. Prioritize certified suppliers and align material choices with operational needs (e.g., cold chain vs. short-term storage). As production scales and regulations tighten, biodegradable options will become increasingly cost-competitive with traditional plastics.

Action Step: Contact 3–5 suppliers for quotes, specifying your required certifications, volume, and film properties. Compare landed costs (price + shipping + tariffs) to identify the best deal.

The terms “compostable” and “oxidative degradation” are often used interchangeably in sustainability marketing, but they describe fundamentally different processes with vastly different environmental impacts. Understanding these distinctions is critical for businesses and consumers aiming to make genuinely eco-friendly choices.

| Term | Definition |

|---|---|

| Compostable | Materials that break down into water, CO₂, and nutrient-rich biomass under specific conditions (e.g., industrial composting) within a defined timeframe (e.g., 90 days). Requires microbial activity and leaves no toxic residues. |

| Oxidative Degradation | A process where plastics fragment into microplastics due to oxygen exposure and additives (e.g., metal salts). Does not fully biodegrade but breaks down into smaller, persistent particles. Often marketed as "oxo-degradable" or "oxo-biodegradable." |

| Factor | Compostable | Oxidative Degradation |

|---|---|---|

| Degradation Process | Broken down by microbes into organic matter. | Fragmented by oxygen/UV light into microplastics. |

| End Products | Water, CO₂, biomass (non-toxic). | Microplastics, chemical residues (toxic). |

| Timeframe | 3–12 months (under ideal conditions). | Months to years (fragments persist indefinitely). |

| Certifications | Requires standards like ASTM D6400, EN 13432. | No legitimate certifications (banned in EU). |

| Environmental Impact | Circular: Returns nutrients to soil. | Pollutes ecosystems with microplastics. |

| Checklist | Compostable | Oxidative Degradation |

|---|---|---|

| Label Claims | Specifies "compostable" with certification logos. | Vague terms like "degradable" or "eco-friendly." |

| Material Type | PLA, PBAT, PHA, or starch blends. | PE, PP with "pro-degradant" additives. |

| Disposal Instructions | Directs to industrial/home composting. | No clear guidance or suggests landfill disposal. |

“Compostable” and “oxidative degradation” represent two ends of the sustainability spectrum:

For genuine sustainability, prioritize certified compostable materials and invest in proper waste management systems. Avoid oxidative-degradable products entirely—they’re a false solution that exacerbates plastic pollution.

Compostable pallet wraps are designed to break down into organic matter, but their effectiveness depends on whether they are processed in industrial composting facilities or home compost systems. Understanding the differences between these two methods is critical for businesses to ensure proper disposal and achieve genuine sustainability outcomes.

| Factor | Industrial Composting | Home Composting |

|---|---|---|

| Temperature | High heat (50–60°C / 122–140°F) | Ambient (20–30°C / 68–86°F) |

| Timeframe | 3–6 months | 6–12 months |

| Certifications | ASTM D6400, EN 13432, TUV OK Compost INDUSTRIAL | TUV OK Compost HOME, AS 5810 |

| Microbial Activity | Optimized with controlled microbes and aeration. | Relies on natural microbes in backyard compost. |

| Infrastructure | Requires access to commercial facilities. | Backyard compost bins or piles. |

Industrial composting facilities use a controlled, high-heat environment to accelerate decomposition:

| Pros | Cons |

|---|---|

| Fast decomposition (3–6 months). | Limited access to facilities (only 15% of U.S. counties have industrial composters). |

| Handles thicker/more complex materials. | Higher costs (50–150/ton disposal fees). |

| Eliminates microplastic risk. | Misplaced wraps (e.g., in landfills) won’t degrade. |

Home composting relies on natural microbial activity in backyard bins or piles:

| Pros | Cons |

|---|---|

| No disposal fees. | Limited to thin films (e.g., <25 microns). |

| Accessible for households/small businesses. | Longer degradation time (6–12 months). |

| Supports decentralized waste management. | Risk of incomplete breakdown in cold climates. |

Industrial and home composting serve distinct roles in managing compostable pallet wraps:

Key Takeaway: Always match your compostable wrap to the disposal method available. For businesses, industrial composting offers scalability, while home composting suits small-scale, consumer-facing applications. Verify certifications rigorously and educate stakeholders to avoid greenwashing pitfalls.

A biodegradable wrap is a type of packaging material designed to break down naturally over time when exposed to environmental conditions such as moisture, heat, or bacteria. Unlike traditional plastic wraps that can take centuries to decompose, biodegradable wraps are made from renewable resources like plant-based biopolymers or polymers with additives (such as D2W) that accelerate the degradation process. Biodegradable wraps are commonly used in industries like logistics, warehousing, and retail to secure and protect goods during transportation and storage. These wraps offer the same durability and stretchability as conventional plastic wraps but break down into organic matter after disposal, leaving no harmful microplastics behind. They are a sustainable alternative to plastic packaging and help businesses reduce their environmental impact while maintaining product security and integrity during transit. Biodegradable wraps can be used for a variety of applications, including pallet wrapping, product bundling, and even food packaging.

While pallet wrap (often made of stretch film) is the most commonly used material to secure products during transportation, several alternatives are available, depending on the type of product and shipping requirements.

Paper Pallet Wrap: An eco-friendly alternative, paper wrap is made from recycled materials and is biodegradable. It is typically used for lighter items and those that do not require extreme durability. While it offers sustainability benefits, it may not be as stretchable or resistant to moisture as plastic or biodegradable wraps.

Strapping: This involves using metal or plastic bands to secure products on a pallet. Strapping is especially useful for securing heavy loads and items that need rigid stabilization. However, it does not offer the same level of protection as wrap against dirt or moisture.

Stretch Hooding: A process where a shrink film is applied over a pallet using heat to create a tight, secure covering. Stretch hoods are highly durable, offering excellent protection during transit. However, they can be more expensive than traditional stretch wrap.

Reusable Pallet Covers: Made from materials such as fabric or plastic, reusable pallet covers can be used multiple times and are an environmentally friendly alternative to single-use wraps. These are ideal for protecting goods during shipping, especially when reused in a closed-loop system.

Corrugated Sheets: These can be used to cover and protect items on a pallet. It is particularly effective for smaller or fragile items and can be recycled after use.

Yes, biodegradable shrink wrap exists and is an eco-friendly alternative to traditional plastic shrink film. Just like standard shrink wrap, biodegradable shrink film is used to tightly secure products or pallets. However, the key difference is that it is made from renewable or biodegradable materials that allow it to decompose naturally after disposal. The most common materials used in biodegradable shrink wrap are plant-based polymers, such as PLA (polylactic acid), or biodegradable additives that accelerate the breakdown process. These films are used in a wide range of applications, including retail packaging, product bundling, and even food packaging. Biodegradable shrink wrap offers the same performance features as traditional plastic shrink film, such as clarity, stretchability, and puncture resistance, but it provides the added benefit of being environmentally friendly. When exposed to appropriate landfill or composting conditions, biodegradable shrink wrap breaks down into harmless substances like carbon dioxide, water, and biomass, reducing the environmental impact of plastic waste. For companies looking to reduce their plastic usage and adopt more sustainable practices, biodegradable shrink wrap is an excellent choice for packaging solutions that require heat sealing.

The recyclability of pallet wrap depends on the material it is made from. Traditional plastic pallet wrap, typically made from low-density polyethylene (LDPE), is technically recyclable, but the process can be challenging. Most curbside recycling programs do not accept plastic films like stretch wrap because they tend to jam machinery at recycling facilities. However, some specialized recycling centers accept these types of plastics, and many businesses have recycling programs in place to handle this waste. For pallet wrap to be recyclable, it should be clean and free from contaminants like adhesives or food residues. On the other hand, biodegradable pallet wrap is not suitable for conventional recycling processes. While it breaks down naturally in composting or landfill conditions, it is not designed to be recycled in the same way as plastic films. However, it provides the benefit of reducing long-term plastic waste, as it decomposes into organic material without leaving microplastics behind. Some biodegradable wraps can be disposed of through composting facilities that handle industrial composting, but it is important to check with local recycling or composting programs to understand the best disposal methods for biodegradable materials.

Biodegradable pallet wrap is primarily made from organic or bio-based polymers that decompose naturally under specific conditions. Common materials include:

PLA (Polylactic Acid): Derived from fermented plant starch (e.g., corn, sugarcane). PLA is rigid and clear but requires industrial composting for degradation.

PBAT (Polybutylene Adipate Terephthalate): A petroleum-based polyester engineered to biodegrade. PBAT offers high elasticity and works well in soil or compost.

PHA (Polyhydroxyalkanoates): Produced by microbial fermentation of plant oils. PHA is marine-degradable and heat-resistant.

Starch Blends: Mixed with biodegradable polyesters (e.g., cornstarch + PBAT) for cost-effectiveness, though they may sacrifice strength.

These materials are often combined to balance performance (e.g., PLA/PBAT blends for flexibility) and degradation efficiency. Certifications like BPI or TUV OK Compost ensure the wrap meets scientific standards for biodegradability.

It depends on the material:

Traditional Plastic (LLDPE):

Recyclable: Yes, through specialized programs, but contamination (dirt, adhesives) often limits recycling rates (<10%).

Not Biodegradable: Takes 500+ years to break down, contributing to microplastic pollution.

Biodegradable Wrap:

Not Recyclable: Mixing biodegradable materials with traditional plastics disrupts recycling streams.

Biodegradable Only Under Specific Conditions: Requires industrial composting (e.g., PLA) or soil/marine environments (e.g., PHA).

Key Takeaway: Traditional wraps prioritize recycling (where facilities exist), while biodegradable wraps focus on composting. Never mix the two in disposal streams.

Proper disposal is critical to ensure biodegradation:

Industrial Composting:

For wraps certified ASTM D6400 or TUV OK Compost INDUSTRIAL.

Locate facilities via tools like FindAComposter.

Home Composting:

Only use wraps labeled TUV OK Compost HOME or AS 5810.

Shred into small pieces to speed up decomposition.

Soil or Marine Disposal:

Use wraps certified TUV OK Biodegradable SOIL/MARINE (e.g., PHA-based films).

Avoid Landfills:

Biodegradable wraps in landfills lack oxygen/microbes and behave like regular plastic.

Note: If no composting options exist, consult suppliers for take-back programs or explore municipal bio-waste collection.

Biodegradable stretch wrap is slightly weaker but can be optimized for most uses:

Tensile Strength:

Biodegradable: 80–90% of traditional LLDPE (e.g., PBAT/PLA blends).

Traditional: Higher elasticity (150–250% pre-stretch capacity).

Puncture Resistance:

Biodegradable films (e.g., PLA) are more brittle; PBAT blends improve toughness.

Workarounds:

Apply 3–5 layers for heavy loads (>1,000 lbs).

Use edge protectors to prevent tears.

Case Study: A logistics firm using PBAT/PLA wraps achieved comparable performance to LLDPE for loads under 1,500 lbs by adjusting machine tension and layering.

Oxo-biodegradable pallet wrap is not truly biodegradable and is considered greenwashing:

Composition: Traditional plastics (PE/PP) mixed with additives (e.g., metal salts) that accelerate fragmentation into microplastics when exposed to oxygen/UV light.

Environmental Impact:

Creates persistent microplastics that pollute soil and water.

Banned in the EU and criticized by the UN Environment Programme.

Certifications: No legitimate certifications; avoid products labeled “oxo-degradable” or “oxo-biodegradable.”

Key Difference: Unlike compostable wraps, oxo-degradable plastics do not break down into organic matter and are harmful to ecosystems.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed