Every year, U.S. warehouses and logistics providers use over 1.2 billion pounds of conventional plastic pallet wrap — enough to stretch around the Earth’s equator 15 times. These petroleum-based films, while cost-effective, silently fuel a mounting environmental crisis: less than 5% are recycled, and most end up in landfills or oceans, leaching microplastics for centuries.

Picture this:

A single truckload of non-recyclable stretch wrap discarded daily translates to 72,000 pounds of plastic waste annually for a mid-sized warehouse. For businesses prioritizing ESG goals or facing tightening regulations (like California’s SB 54), sticking with traditional wraps isn’t just unsustainable—it’s a growing liability.

But what if you could protect shipments and the planet without sacrificing performance?

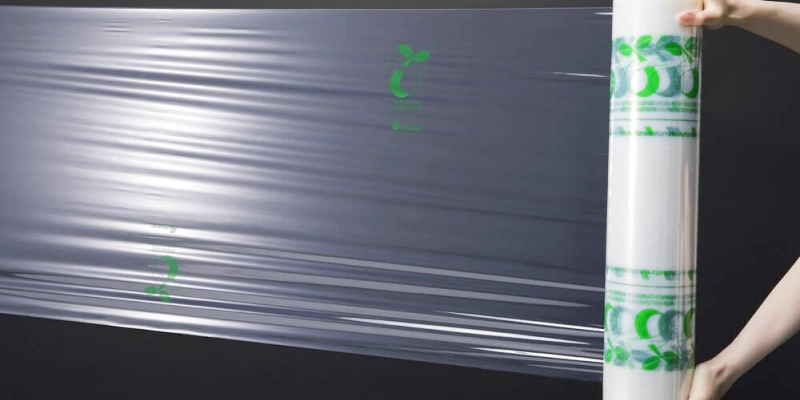

Eco friendly pallet wrap offers a solution by helping reduce single-use plastic waste, which often ends up in landfills, contributing to pollution and environmental degradation. By choosing eco friendly pallet wrap, companies can support greener supply chains and demonstrate a commitment to responsible packaging. This sustainable choice not only aligns with corporate environmental goals but also meets consumer expectations for eco-conscious practices, making it a valuable option in today’s sustainability-focused market.

In recent years, several sustainable alternatives to traditional plastic pallet wrap have emerged, each designed to meet the growing demand for environmentally responsible packaging. Eco friendly pallet wrap options offer solutions that reduce plastic waste while providing reliable protection and stability for palletized loads. Here are some of the best eco friendly pallet wrap options currently available, each with unique benefits in terms of durability, reusability, and recyclability:

Made from post-consumer recycled materials, recycled pallet wrap significantly reduces the need for virgin plastic production. By reusing materials already in circulation, this option contributes to a circular economy, conserving resources while lowering environmental impact.

Biodegradable pallet wrap is formulated to break down naturally over time, offering a more environmentally-friendly alternative to standard plastic. Often incorporating additives that speed up the degradation process, biodegradable wraps reduce long-term waste in landfills. Biodegradable hand stretch film serves as a similar eco-friendly solution, providing a manual wrapping option that breaks down naturally, making it ideal for smaller-scale applications while helping to reduce plastic waste.

Compostable pallet wrap takes sustainability a step further by fully breaking down into organic materials, leaving no plastic traces. This type of wrap can be disposed of in composting environments, where it turns into nutrient-rich compost for soil.

Reusable pallet wrap, made from durable materials, is designed for repeated use in transport and warehousing. By investing in reusable wrap, companies can reduce both plastic waste and costs associated with single-use products.

Each of these eco friendly pallet wrap options offers practical solutions for companies aiming to reduce their environmental footprint while maintaining effective load security. Choosing the right option depends on specific needs, such as recyclability, reusability, and the end-of-life disposal method, allowing businesses to adopt sustainable practices in their operations.

Pallet wraps, commonly used to secure goods during transportation and storage, have traditionally relied on petroleum-based plastics like linear low-density polyethylene (LLDPE). However, growing environmental concerns have driven the development of eco-friendly alternatives. Below is a detailed breakdown of sustainable pallet wrap material types, their properties, benefits, and challenges.

These materials break down naturally via microbial action under specific conditions (e.g., industrial composting facilities). They are designed to reduce long-term plastic pollution.

These wraps incorporate post-consumer or post-industrial recycled materials, reducing virgin plastic use.

These materials are derived from renewable resources but may not biodegrade. They aim to reduce fossil fuel dependence.

A return to traditional materials with modern innovations for pallet wrapping.

While not a material, reusable systems eliminate single-use wrap entirely.

Combining materials to balance performance and sustainability.

By understanding these material types, businesses can select pallet wraps aligned with their sustainability goals, operational needs, and regulatory requirements.

Here’s a comparison table for tensile test data between eco-friendly films (e.g., biodegradable or bio-based) and traditional plastic films (e.g., LLDPE). The values provided are generalized averages and may vary based on specific formulations and testing standards (e.g., ASTM D882 or ISO 527):

| Property | Eco-Friendly Film (e.g., PLA/PBAT Blend) | Traditional Film (LLDPE) | Units | Notes |

|---|---|---|---|---|

| Tensile Strength | 25 – 45 | 20 – 35 | MPa | Eco-friendly films often match or exceed traditional films in strength. |

| Elongation at Break | 100 – 300 | 500 – 700 | % | Traditional films are more stretchable; eco-films may be brittle. |

| Young's Modulus | 1,500 – 3,000 | 200 – 400 | MPa | Eco-films are stiffer (higher modulus) compared to flexible LLDPE. |

| Yield Strength | 15 – 30 | 10 – 20 | MPa | Eco-films typically exhibit higher yield strength. |

| Tear Resistance | 40 – 80 | 50 – 100 | N/mm | Traditional films generally have better tear resistance. |

| Density | 1.2 – 1.3 | 0.91 – 0.94 | g/cm³ | Eco-films are denser due to bio-based polymers. |

| Biodegradability | 90%+ in 180 days (industrial composting) | Non-biodegradable | — | Eco-films degrade under specific conditions; LLDPE persists for centuries. |

| Recyclability | Limited (requires specialized streams) | Widely recyclable | — | Traditional LLDPE has better recycling infrastructure. |

| Moisture Resistance | Moderate to Low | High | — | Some eco-films (e.g., PLA) absorb moisture, affecting performance. |

| Temperature Resistance | 50 – 60°C | 80 – 100°C | °C | Traditional films withstand higher temperatures. |

This table helps evaluate whether eco-friendly alternatives meet mechanical requirements for specific pallet-wrapping use cases.

Adopting eco-friendly pallet wraps involves evaluating both direct and indirect costs compared to traditional plastic wraps (e.g., LLDPE). Below is a comprehensive cost analysis, covering material, production, logistics, waste management, and long-term financial implications.

| Cost Component | Conventional Wrap | Eco-Friendly Wrap | Δ (Eco vs. Conv.) |

|---|---|---|---|

| Material Cost | $18.00 | $19.80 (+10 %) | +$1.80 |

| Disposal/End-of-Life | $0.50 (landfill fee) | –$0.20 (recycling rebate) | –$0.70 |

| Regulatory Fees/Incentives | +$0.05 | –$0.10 (rebate) | –$0.15 |

| Damage-Prevention Savings | $0.00 | –$1.00 | –$1.00 |

| Total Cost per Pallet | $18.55 | $18.50 | –$0.05 |

While eco-friendly pallet wraps have higher upfront costs (20–50% premium), their TCO becomes competitive over time due to:

Eco-friendly pallet wrap, also known as sustainable stretch film or green pallet wrap, is a packaging material designed to secure goods on pallets during storage and transportation while minimizing environmental impact. Made from biodegradable, compostable, or recyclable materials (e.g., plant-based polymers, recycled plastics), it addresses growing demand for sustainable supply chain solutions. Below are detailed applications across industries:

Eco-friendly pallet wrap is no longer a niche product but a critical tool for industries aiming to balance operational efficiency with planetary stewardship. Its versatility ensures relevance across sectors, driven by innovation, regulation, and consumer expectations.

Certifications are critical for validating the environmental claims of eco-friendly pallet wraps, ensuring they meet specific sustainability, safety, and performance standards. Below is a detailed breakdown of key certification systems and their relevance to biodegradable, compostable, or recyclable pallet wraps:

Certifications for eco-friendly pallet wraps build trust with consumers, regulators, and supply chain partners. By aligning with recognized standards, manufacturers and users can ensure compliance, reduce greenwashing risks, and contribute to a circular economy.

1. Check Material Composition

→ Choose PLA, PBAT, or compostable starch blends.

→ Avoid oxo-degradable plastics (they create microplastics).

2. Verify Certifications

→ Look for ASTM D6400, EN 13432, or OK Compost labels.

→ Ensure they match your disposal method (e.g., industrial composting).

3. Test Performance

→ Assess tensile strength, cling, and puncture resistance.

→ Trial samples under real transport conditions.

4. Confirm Disposal Options

→ Check if local facilities accept the wrap (e.g., composting access).

→ Avoid products requiring unavailable infrastructure.

5. Evaluate Suppliers

→ Prioritize transparent brands with third-party certifications.

→ Request documentation on biodegradability claims.

6. Compare Costs & Benefits

→ Balance upfront cost vs. eco-compliance and long-term sustainability goals.

Key: Ensure durability aligns with needs while meeting genuine biodegradability standards.

Alternatives to traditional pallet wrapping offer environmentally friendly solutions that reduce plastic waste and promote sustainability. Popular eco-friendly alternatives include paper stretch wrap, reusable pallet wraps, pallet bands, and strapping.

Paper Stretch Wrap: Made from renewable materials, paper stretch wrap is biodegradable and can be recycled, making it an excellent choice for companies aiming to reduce plastic usage. It works well for smaller loads and lighter products.

Reusable Pallet Wraps: Constructed from durable, long-lasting materials, reusable pallet wraps are designed for repeated use, making them cost-effective in high-frequency transport settings. Ideal for closed-loop systems, they allow businesses to secure goods without generating plastic waste.

Pallet Bands: These large, elastic bands hold items in place on pallets and can be used multiple times, offering an economical and sustainable solution. Pallet bands are best suited for stable, uniform loads that don’t require extensive protection.

Strapping: Typically made from metal or eco-friendly materials, strapping secures pallets without additional wrapping. It’s easy to apply and highly recyclable, but it’s more effective for consistent load shapes.

Each alternative addresses different needs based on load size, frequency of use, and sustainability goals, allowing companies to choose the right option to replace conventional pallet wrapping.

Yes, plastic pallet wrap can be recycled, but certain conditions must be met for effective recycling. Most pallet wraps are made from linear low-density polyethylene (LLDPE), a type of plastic that is recyclable if collected and processed correctly. However, recycling facilities typically require that the wrap be clean and free of any non-plastic components, like labels or tape, to prevent contamination in the recycling stream.

To recycle plastic pallet wrap, companies can partner with facilities that accept LLDPE film or specific recycling programs designed for flexible plastic. Some businesses even work with providers that collect used plastic wraps and repurpose them into new materials, supporting a circular economy. However, not all locations have convenient access to plastic film recycling, so checking with local recycling authorities is essential.

Using recyclable plastic pallet wrap helps reduce the environmental impact, but it’s even more effective when paired with alternatives like biodegradable or reusable options that further decrease waste.

My name is James Thompson, and I’m the editor of this website dedicated to Stretch Film, Pallet Wrap, and Stretch Wrap products.

My passion for packaging began when I noticed the challenges companies face in securing their products efficiently for transportation and storage. This inspired me to delve deep into the world of stretch films and pallet wraps, exploring the latest technologies and best practices.

I aim to provide valuable insights, practical tips, and up-to-date industry trends to assist you in making informed decisions. Whether you’re a small business owner or part of a large corporation, my goal is to support you in optimizing your operations and ensuring your products reach their destination safely.

Thank you for visiting, and I look forward to accompanying you on your journey toward better packaging solutions.

Comments are closed